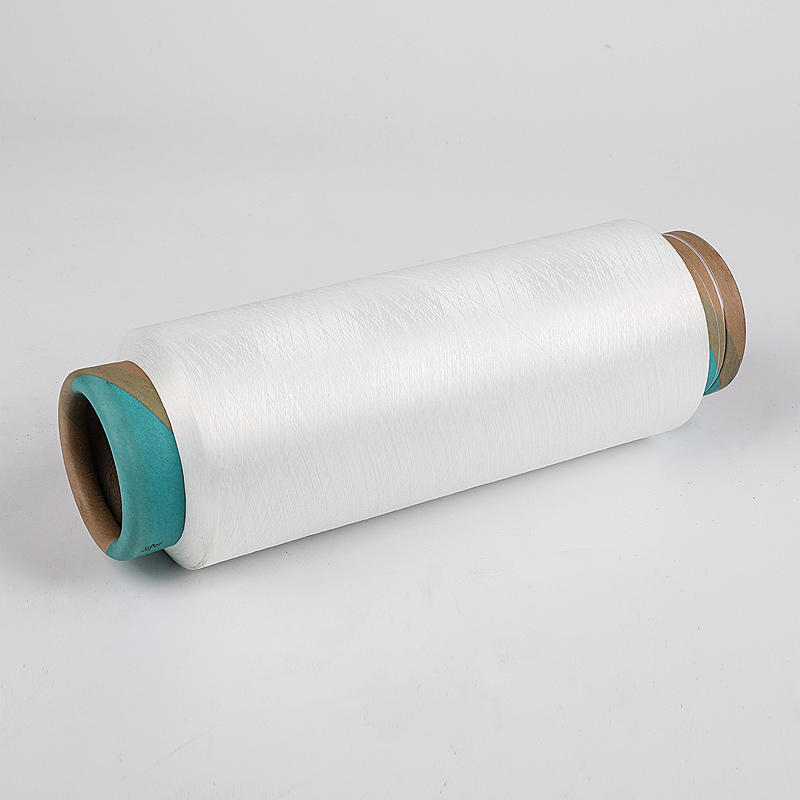

Heating Polyester Yarn

Adding nano-thermal materials in the spinning process can effectively absorb and emit far infrared rays, achieving the effect of heat storage and warmth. The fabric of this product has long-lasting heat storage function, can provide safe far infrared ray, make the clothing warm and comfortable, at the same time the natural material is harmless to the body, skin-friendly and comfortable.

Specification

30-500D/36-576F

Test standard: GB/30127-2013 Test index: Far infrared emissivity ≥ 0.88 Far infrared radiation temperature rise ≥ 1.7 ° C

Measured value: far infrared emissivity is 0.92/far infrared radiation temperature rise 2.6 ° C

Application fields:bed sheets,underwear,down jacket,socks

We are leader Heating Polyester Yarn manufacturers and factory which produce heated yarns that meet the highest standards of quality and performance. We also invest in advanced equipment and technology to increase the efficiency and quality of heating processes.

Industry Knowledge

What Is Heating Polyester Yarn?

Heating polyester yarn is a process of subjecting the yarn to high temperatures to modify its physical properties. The heating process can be done through various methods, such as hot air, steam, or infrared radiation. The primary purpose of heating polyester yarn is to improve its stability and durability. The process can help to set the twist and increase the yarn's strength, elasticity, and resistance to shrinkage. It also improves the yarn's appearance and texture, making it smoother and more even. Heating polyester yarn can be done at different stages of the manufacturing process, such as after spinning, weaving, or knitting. The exact temperature and duration of the heating process depend on the type of polyester yarn and the desired properties.

Benefits of the Heating Polyester Yarn

Polyester is a popular synthetic fiber that is widely used in clothing, bedding, and other textiles. When polyester yarn is heated, there are several benefits that can be obtained:

1. Improved elasticity: Polyester yarn can become more elastic when heated, which can be useful in creating fabrics that need to stretch and recover, such as sportswear or swimwear.

2. Better dye absorption: Heating polyester yarn can also help to open up the fibers, allowing them to better absorb dyes and colors, resulting in brighter and more vibrant hues.

3. Reduced shrinkage: Polyester is known for its resistance to shrinkage, but heating the yarn can further reduce the risk of shrinkage, making it a popular choice for items that need to maintain their shape after washing.

4. Enhanced durability: When polyester yarn is heated, the fibers become more tightly woven, which can make the resulting fabric stronger and more durable.

5. Improved texture: Heating polyester yarn can create a softer, smoother texture, making it more comfortable to wear or use.

Overall, heating polyester yarn can enhance its performance and make it more versatile, making it a popular choice for a wide range of textile applications.

What is the Heating Polyester Yarn mainly used for?

Polyester yarn can be heated to improve its properties and make it suitable for various applications. The heating process can include texturizing, heat setting, and annealing, among other techniques.

Heating polyester yarn can make it more elastic, bulkier, and softer, depending on the specific application requirements. Some of the main uses of heated polyester yarn include:

1. Textile industry: Polyester yarn is commonly used in the production of a wide range of textiles, including clothing, home textiles (such as curtains and upholstery), and industrial fabrics. Heating the yarn can improve its texture and make it more suitable for specific textile applications.

2. Carpet industry: Heated polyester yarn can be used in the production of carpets and rugs, where it provides durability, stain resistance, and colorfastness.

3. Packaging industry: Polyester yarn can be used in the production of various types of packaging, including bags, pouches, and films. The heating process can improve the yarn's properties, such as its tensile strength and dimensional stability, making it more suitable for packaging applications.

4. Automotive industry: Heated polyester yarn can be used in the production of automotive textiles, including seat covers, headliners, and carpets. The yarn's improved properties make it more resistant to wear and tear UV radiation, and temperature extremes.

Overall, heating polyester yarn can improve its properties and make it suitable for a wide range of applications across various industries.

中文简体

中文简体 English

English Español

Español

TEL: +86-575-85510907

TEL: +86-575-85510907 E-mail:

E-mail:  Qianqing Material Market, Shaoxing,Zhejiang Province,China

Qianqing Material Market, Shaoxing,Zhejiang Province,China